Shopping cart

No products

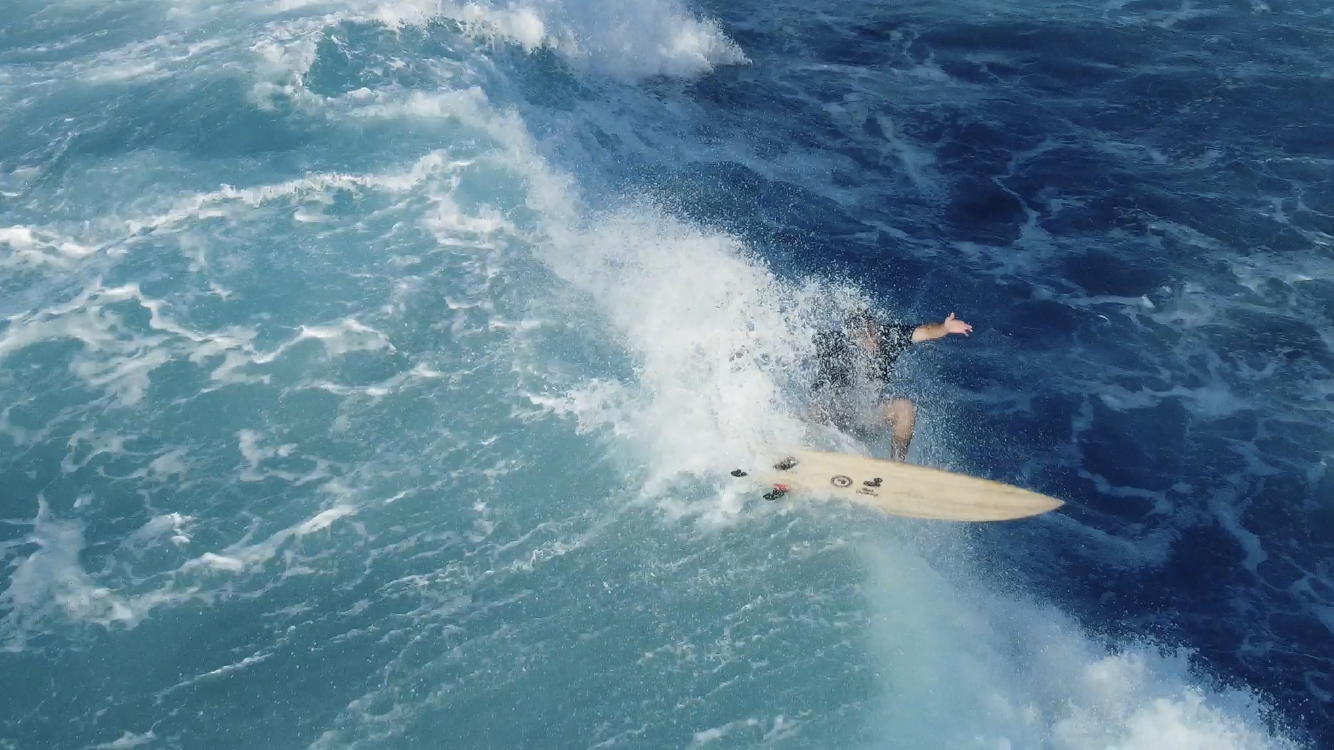

FlamaVolta is an open source technology for pushing the limits of sustainable surfboard construction, specially addressed to surfboard artisans. A process that emulates the same steps involved in traditional surfboard construction, while opening the door to refusing all the toxic materials we’ve been working with for too long.

//

|

![]()

//

|

![]()

//

|

![]()

//

TECHNOLOGY AND MATERIALS

Vacuum bagging lamination An easy, cheap and user-friendly tech that allows a perfect and strong lamination. From boats hulls to household appliances to space shuttles, vacuum bagging is how composite materials are done today.

Veneer wrap –the Volta– Amazingly, paulownia veneer (and also other timbers) can wrap around the rails easily with very little practice. Organic cloth Flax and hemp cloth are superstrong fibers with even superior tensile strength than fiberglass. When combined with veneer they become a bulletproof lamination. Biobased epoxi and PU glue Both Epoxi or PUglue can be used in the process. The advantage of PUglue is that is more flexible than Epoxi and is very easy to work with, with no issues with temperature or humidity. Shaping In opposition to other wooden technologies where you need to consider the thickness of the skins, the board can be handshaped as if it was to be fiberglassed. Paulownia wood blocks Nose and tail blocks add protection and help prevent leaks through the cloth lamination in these delicate places, as paulownia is water resistant. Fin wood blocks make for a super strong finbox bond and can be used with any fin system.

Decoration meets performance Playing with different timbers not only gives a beautiful look, but it can be used to reinforce specific areas. Wood floor varnish as a finish No more hot coats, easy finishing, weather friendly, cheap and makes DIY repairs easy. |