|

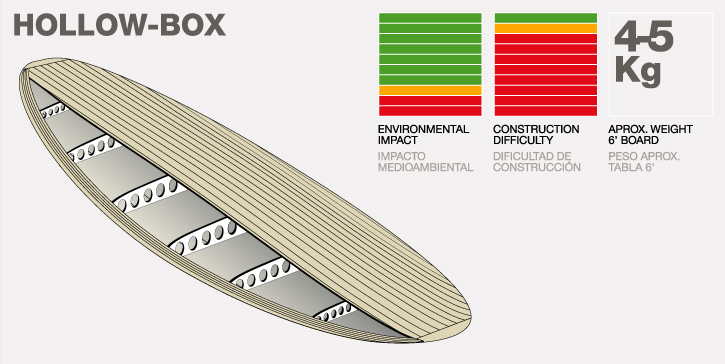

HOLLOWED OUT WOOD STRIPS, GLUED UP LONGITUDINALY.

The most basic of all methods, it was introduced during the balsa+fibreglass era, but it was quickly put aside with the introduction of poliurethane foam.

SEALING

Usually glassed, but depending on the kind of wood they can be varnished or oiled.

MOST USED WOODS

Balsa, paulownia, red cedar, agave.

ADVANTAGES

- Done properly, makes a very strong board.

- Apreciably lighter than a solid one.

- Very few joints.

- With the right wood doesn’t need to be glassed (but keep joins perfecly sealed!).

DISADVANTAGES

- Many hours of very complicated hand work.

- Big waste of material due to the chambering process.

- Without the experience and the right tools, shaping the foil and rocker from a flat wood blank can be quite difficult.

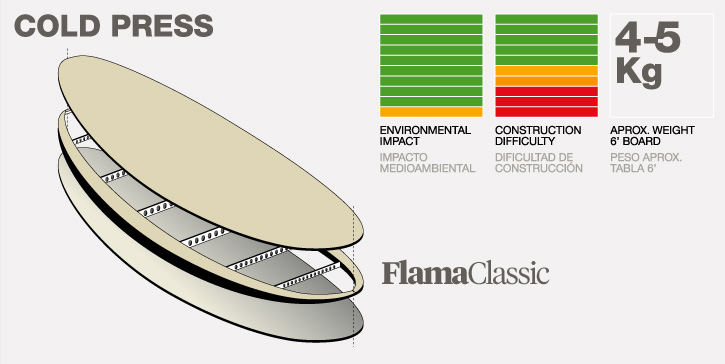

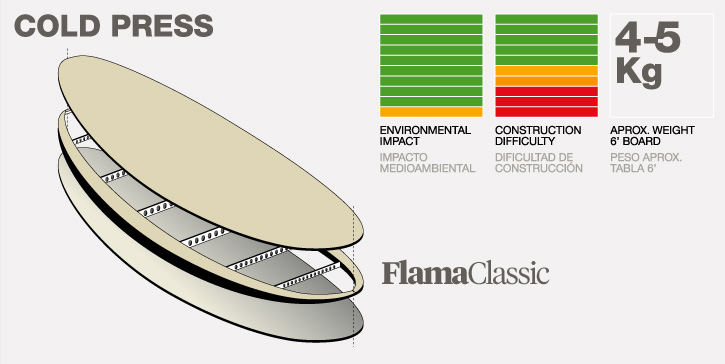

WOOD PANELS COMPRESSED AND BENDED AGAINST AN INTERNAL FRAME.

In essence, it's the same concept that Tom Blake used to make his second generation of hollow surfboards in 1929 that made him famous. It was also our choice to make our FlamaClassic boards.

SEALING

Depending on the kind of wood they can be glassed, varnished or oiled.

MOST USED WOODS

Paulownia, balsa, red/white cedar.

ADVANTAGES

- Pretty simple process of production.

- Thicker rails give a good strength to the board.

- Lighter than chambered or hollow boards (if it's not glassed!).

- Very few joints.

- It can be mass produced.

- Cold press means that little energy is needed (none with a manual press).

- With paulownia wood doesn’t need to be glassed.

DISADVANTAGES

- Needs a kind of wood capable of bending without cracking.

- Milling the internal frame is pretty tricky.

- Risk of weakening the board by too much shaping.

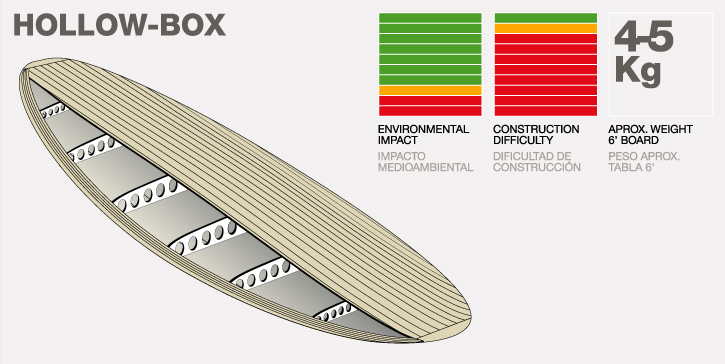

THIN STRIPS OF WOOD OVER AN INTERNAL FRAME, TIED TOGETHER IN TORSION.

This construction concept was taken from wooden boatbuilding and today is perhaps the most popular because it can be sold as a DIY kit.

SEALING

Always glassed in order to seal the huge amount of joints.

MOST USED WOODS

Red/white cedar, redwood, paulownia, poplar, and cork in boards with solid rails.

ADVANTAGES

- Saves on materials in comparison to chambered boards.

- With the right estructure they can be lighter than chambered or cold-press constructions.

- Can be mass-produced easily and sold in kits.

- Can be selfmade in a garage.

DISADVANTAGES

- Many hours of very complicated hand work.

- Trying to reduce too much weight can lead to a weak surfboard.

- There are so many joints that fiberglassing is obligatory.

- Every piece of wood needs to be cut precisely (CNC cut reccomended).

- They are expensive (unless you do it yourself!).

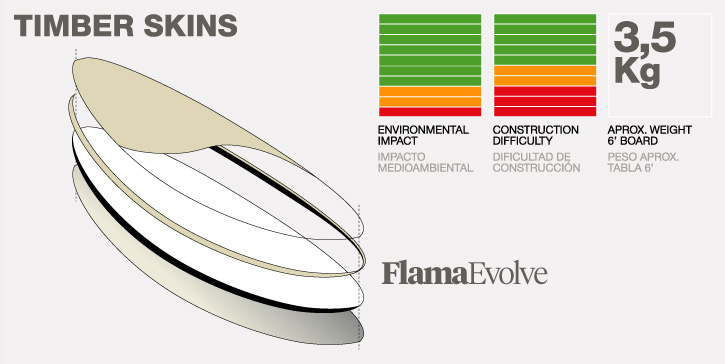

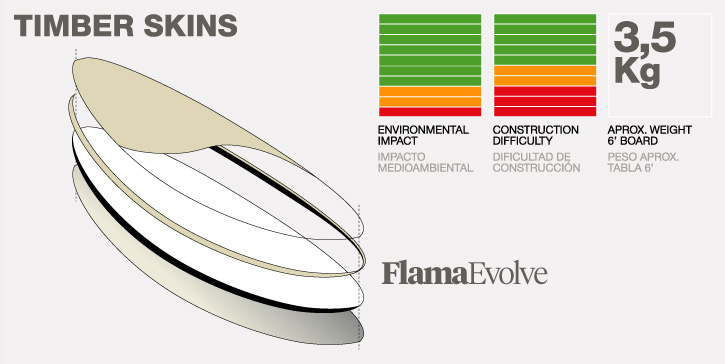

INNER CORE AND PARABOLIC STRINGERS, COVERED WITH A WOOD SKIN.

A vacuum-press laminating technique widely used in the industry, very versatile, that can work with a wide variety of materials

SEALING

Fiberglassing can be avoided depending on the materials used.

MOST USED WOODS

Red/white cedar, redwood, paulownia, poplar, cork...

ADVANTAGES

- Makes very light, solid and high performance boards.

- In combination with timber it can reduce (or completely eliminate) the use of fiberglass.

- The versatility of this technique offers endless possibilities and a promissing future.

DISADVANTAGES

- Expanded polysyrene (EPS), although it’s 100% recyclable, it’s a derivative of petroleum and is not biodegradable. But it seems that pretty soon there will be organic foams available in the market... let's hope for it!

|